Our Projects

PROJECT INNOSMAD

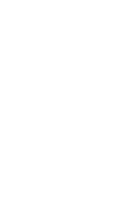

Funded under the Interreg V-A Italy-Switzerland cooperation program, the project has as its objective the in-depth study of metal systems based on shape-memory alloys (SMA) with regard to the use of inherent damping properties. The project is focused on investigating and evaluating the potential use of SMAs as vibration dampeners in the aerospace, naval, medical and sports fields, culminating in the establishment of an Italian-Swiss collaborating network that may involve the largest number of sectors and companies. Within this project, Technosprings developed and produced demonstrative shock absorption and vibration dampening devices for industrial applications. For more information please consult: https://progetti.interreg-italiasvizzera.eu/it/b/78/nuovimaterialiesoluzioniperlosmorzamentodivibrazioni

PARTENARIATO DI PROGETTO:

- CNR ICMATE Lecco Consiglio Nazionale delle Ricerche - Istituto di Chimiche delle Materia Condensata e Tecnologie per l’Energia

- CSEM Centre Suisse d’ Electronique et de Microtechnique SA

- Technosprings Italia s.r.l.

- TSS InnovationsProjekte GmbH

PROJECT GSTP 6.1

HT-SMA HDRA - Hold Down and Release Actuator based on High Temperature Shape Memory Alloy

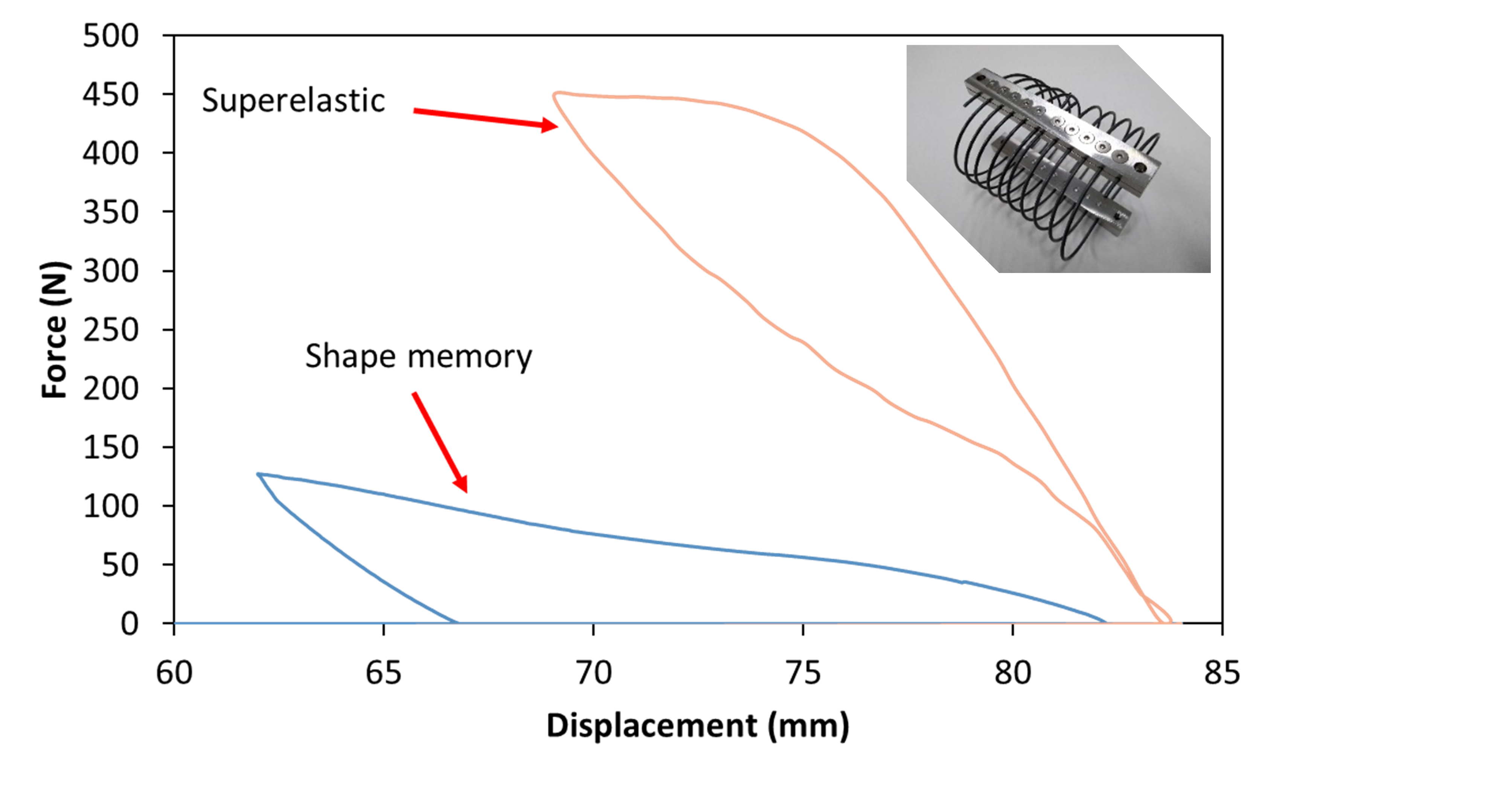

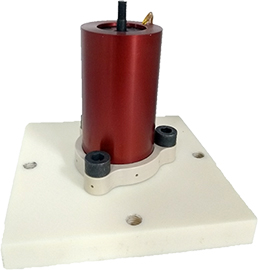

Technosprings took part as a consultant in the project funded by ESA - European Space Agency (4000123630/18/NL/PS/gp), developing a Hold Down Release Actuator (HDRA), that is, the heart of a release mechanism for aerospace applications. During the project the devices have been designed, manufactured and tested following the requirements of ECSS specifications, and the project ended with the achieving of TRL4.

Technical and functional characteristics:

- Resettable and reusable (qualified for 10 grounded + 1 in-orbit activations)

- 10mm linear actuation

- Traction force: 30N axial + 20N cutting

- Ø40 mm x L 80 mm, 180g

- Activation time approx. 3 min @ RT, 90W

- Operating temperature -50°C ÷ 125°C

- Activation temperature > 140°C

- Redundant working and power system

- Monocrystalline HT-SMA CuAlNi material

Qualification tests:

- Activation with 1 heating circuit

- Activation with 2 heating circuits

- RT activation after keeping it at -60°C

- RT activation after keeping it at 200°C

- RT activation after sinusoidal and random vibrations

- RT activation after shock

- Activation at -50°C in a vacuum

- Activation at +125°C in a vacuum

- RT looping for 210 activations

PROJECT PARTNERSHIP:

- ESA European Space Agency

- TSS InnovationsProjekte GmbH

- HES-SO Valais-Wallis

- Technosprings Italia S.r.l. – consulting

PROJECT CLEANTOOLS

Leghe a memoria di forma e Saldatura Rotativa a Frizione per la realizzazione di strumentario chirurgico flessibile.

Shape-memory alloys and rotary friction welding for the construction of flexible surgical instrumentation.

Technosprings took part in the European “Cleantools” project, fundad by the European Commission, during the 7th Framework Programme, developing a new rotary friction welding method to weld Nitinol and stainless steel using a bio-compatible support material.

The group of companies, research centres and universities that worked on Cleantools project developed a rotary friction welding procedure that demonstrated the possibility of creating junctions between dissimilar materials presenting mechanical properties adequate for the production of flexible surgical instrumentation, such as intramedullary milling cutters, reducing the part count.

The use of a Nitinol rod, with superelastic properties, allowed testing the effectiveness of the milling cutter on curved bones, as the cutter can rotate even with its rod bent. Further benefits highlighted by this project are the possibility to produce surgical instrumentation which is easy to sterilise because free of interstitial spacings between parts, such as for instance the milling cutters currently on the market, which are made of spiral-wound parts and mechanical joints, presenting cavities or accumulation areas of biological deposits.

The Cleantools consortium, and Technosprings in particular, is confident that it will be able to bring this new Nitinol processing technology on the market, and is therefore actively looking for business partners interested in new applications. More information can be found at www.cleantools.de

The project was funded by the European Commission trough the Settimo Programma Quadrato per la Ricerca, lo Sviluppo Tecnologico e la realizzazione di Dimostratori (Seventh Framework Programme for Technological Research and Development and the realisation of Demonstrative devices), and it is regulated by the contract nr. 286888.

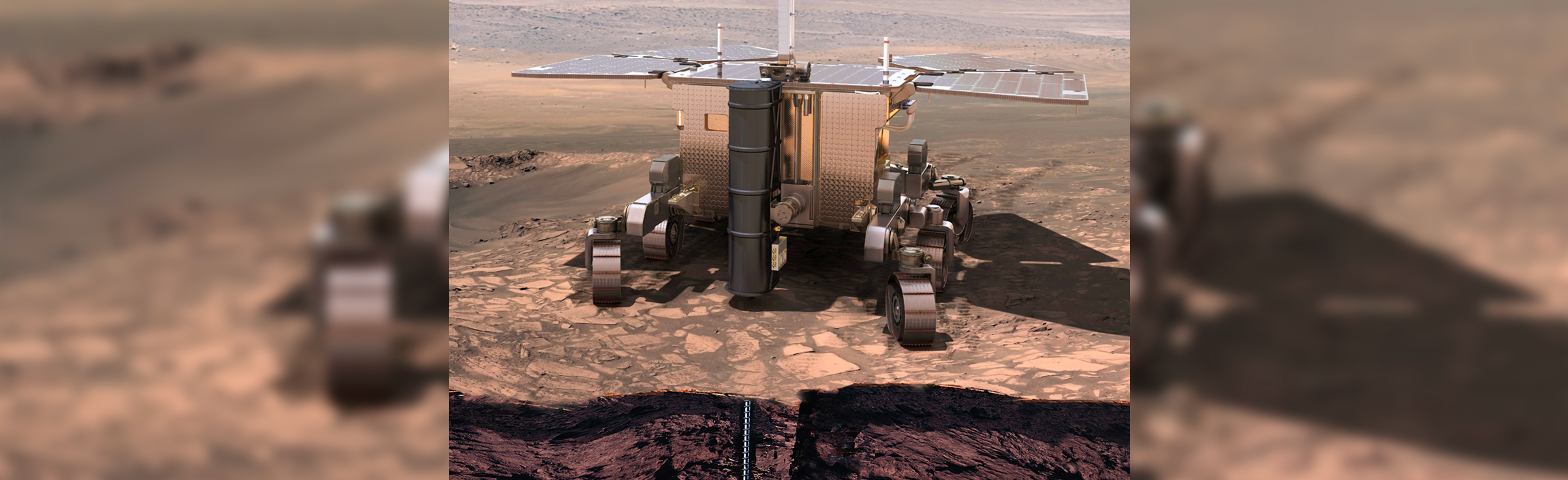

PROJECT SHREK (Shockless release Kinematic)

Shape-memory mechanism for fastening and separating satellite and aviation modules and payload – ID 30105284

PROJECT PARTNERSHIP:

SELEX ES (Nerviano - MI): Project leader, System Integration and Qualification AEREA S.p.A. (Milano - MI): Project, Development and Industrial Property TECHNOSPRINGS Italia S.r.l. (Besnate - VA): Development of Shape-Memory Actuator CNR-IENI (Lecco - LC): Characterisation of Shape-Memory Alloys

RESEARCH OBJECTIVES:

• Deployment of solar panels for use in space (size 21 mt x 1 mt, mass 10 kg) • Technology entirely developed in Europe • Actuator made in shape-memory alloy and torsionally stressed • Shockless actuation • Reversible operation • High number of actuation with phase transition • Unlimited manual activations • Lubrication free • Cleanliness: no emission of contaminating particles • Limited electrical consumption (20 W max) • Limited mass (<= 400 g) • Small size (84 x 37 mm)

PROJECT SAPERE/STRONG

Construction of an SMA element-based valve for refuelling

Exploration of space and of space access: STRONG (Systems, Technologies and Research for Global National Operability)

Strategic objectives:• Maximum operational involvement of national assets • Aumento dell’uso di VEGA • Increased use of VEGA • Preparation for space exploration

Tecchnical objectives:• Putting into orbit the highest possible P/L, using the VEGA vector • Returning to earth significant samples of P/L by use of the IXV Evolution re-entry vehicle • Using the ISS as space “reference port” (Space Port) • Developing and demonstrating selected critical technologies enabling this operational scenario and the future space exploration

STRONG (Systems, Technologies and Research for Global National Operability)

Main elements of the overall scenario:• VEGA launcher used to launch the maximum payload into LEO • A standard, modular P/L platform that fits into the VEGA fairing • An electrically propelled space tug to haul the P/L platform from LEO to the required final orbit (and vice versa) • A tank on the ISS for the recurring refuelling of the space tug • The IXV Evolution vehicle to return to earth samples of P/L • A Ground Station & Infrastructures for mission control, particularly of its non-standard phases involving the space tug and ISS

PARTNERS