SHAPE-MEMORY ELASTIC ELEMENTS

for industrial applications

“Flexibility is within our DNA” is not merely a catch phrase but a modus operandi that characterises us. Technosprings Italia S.r.l. designs, creates prototypes and produces smart devices and elastic elements, using shape-memory materials. Shape-memory materials are an innovative class of materials offering unique properties such as shape recovery by simple heating (Shape Memory Effect) or the capacity to withstand large strains with no yielding (Superelasticity). Starting from the knowledge of the functional properties of shape-memory materials, in recent years Technosprings gained a significant experience in cold working and end properties’ optimisation of its manufactured devices, offering solutions that can be embedded into its customers’ products.

Our productive environment has always offered high quality standards in large-scale production, when processing traditional materials. Such skill was integrated in the production processes of shape-memory items perfectly, guaranteeing reproducibility and reliability of functional properties. Elastic elements in shape-memory alloy are extensively used In many industries, particularly in the air conditioning, thermohydraulic and automotive sectors as actuators in flow direction regulators, in the fire prevention sector as safety components, and also in the biomedical sector in the manufacturing of fixation devices of bony portions after traumatic events.

Flexibility is our own DNA

PSEUDOELASTICITY:

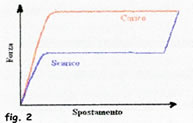

IWe have previously seen the application of NiTi alloys in the eyewear frames industry. Few people know that some models of mobile phone antennas are made with these materials, as well as they find vast application in the field of orthodontics.The harnessed quality in all such cases is the peculiar mechanical response of shape-memory wires shown schematically in figure 2. It is important to observe how in the loading phase a region appears (red line) in which there is no increase of load with the increase of deformation, and similarly so in the unloading phase.

It is therefore possible to deform the material, even very severely (up to 6 – 8 %), without detecting a significant increase in its resistance.

SHAPE RECOVERY:

NiTi alloys can be used in shape recovery mode in three ways: 1. Free recovery: recovery occurs freely. For instance, in the gadget sector, or in the development of small devices that retain a preordained form, usually by simple heating of a few degrees higher than ambient temperature. 2. Constrained recovery: in case it is impeded by a non-yielding constraint.That is the case when shape recovery is impeded by a constraint; in such case the attempt to recover the shape is converted in an effort that can be usefully employed to set up connections. 3. Actuators: in case the constrain yields according to some law to the effort deployed by the material during the shape recovery, making the system’s replication feasible.

The most known scheme is that shown schematically in figure 3, where a shape-memory spring is operated as an antagonist to a normal steel spring. The different elasticity module that the shape-memory material exhibits at high and low temperatures is thus leveraged. At low temperature the material has a module such that the steel spring just overcomes the resistance of the shape-memory spring, keeping it in the compressed position; by increasing the temperature up to the transformation point the shape-memory spring will compress the antagonist steel spring instead, thus achieving a cursor movement to the opposite end. Once the spring cools down, the system will return to the initial configuration, ready to repeat that actuation.